Ihr Partner für

EMS Dienstleistung

News, Messen & Aktuelles

News

a.p. microelectronic

Qualität made in Germany.

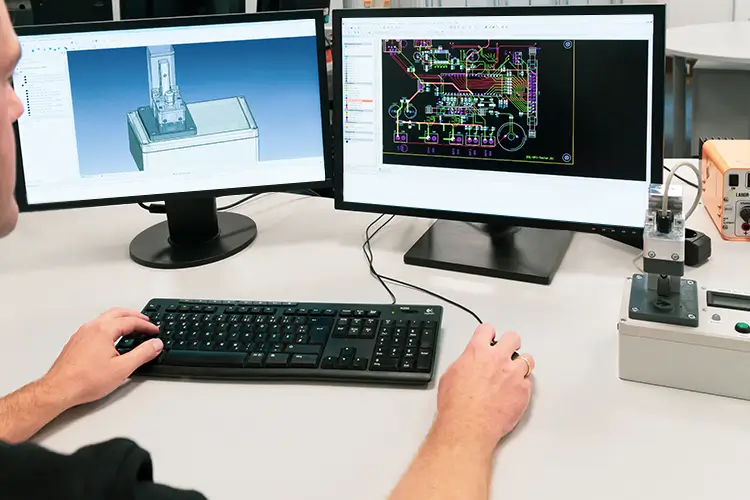

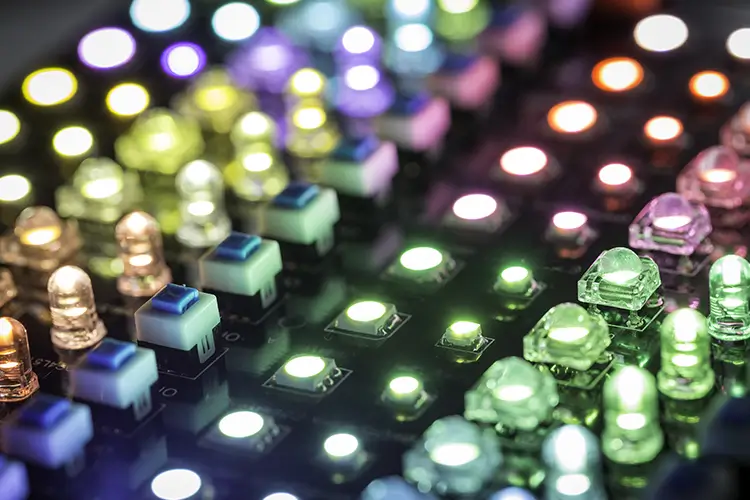

a.p. microelectronic wurde im Jahr 1984 gegründet und ist durch kundenspezifische Entwicklungen international tätig. Als EMS-Dienstleister (Electronic and Manufacturing Services) entwickeln und fertigen über 70 Mitarbeiter für Kunden im In- und Ausland serienreife Elektroniken.

Das Produktportfolio umfasst Entwicklungen für Steuer-Elektroniken und Sensorik für Automotiv-, Medizin-, Maritime- und Industriekunden.

- System-Lieferanten für elektronische und mechatronische Baugruppen

- Fachabteilungen mit modernsten Konstruktions-, Produktions- und Prüfanlagen

- Lieferant der Automobilindustrie nach den aktuellen Standards zertifiziert

a.p. microelectronic

Wir wissen, wie moderne EMS-Dienstleistung geht.

a.p. microelectronic GmbH bietet Ihnen als Kunden aus den verschiedensten Branchen ein Komplettpaket mit umfassenden Dienstleistungen an.

Unser Team wird Sie von der Entwicklung bis zur Serienfertigung begleiten und mit kompetenter Fachberatung unterstützen.

a.p. microelectronic

Wir wissen, wie moderne EMS-Dienstleistung geht.

a.p. microelectronic GmbH bietet Ihnen als Kunden aus den verschiedensten Branchen ein Komplettpaket mit umfassenden Dienstleistungen an.

Unser Team wird Sie von der Entwicklung bis zur Serienfertigung begleiten und mit kompetenter Fachberatung unterstützen.

Service

EMS-Dienstleistungen auf einem modernen Niveau.

"Wir wissen, dass sich eine moderne EMS-Dienstleistung heutzutage längst nicht mehr auf reine Leiterplattenbestückung beschränkt."

a.p. microelectronic GmbH bietet Ihnen als Kunden aus den verschiedensten Branchen ein Komplettpaket mit umfassenden Dienstleistungen an.

Produkte

"Von der Entwicklung über die Anfertigung von Prototypen bis hin zur Serienfertigung begleitet Sie unser Entwicklungs- und Projektteam."

Die Produktion erfolgt bei a.p. microelectronic grundsätzlich unter kontrollierten Bedingungen. Das stellen wir durch die Überwachung der Schlüsselprozesse und zwischengeschaltete „Quality Breakpoints“ sicher.

Kundenspezifische Anforderungen wie Montage- oder Fertigungsanweisungen, einschließlich besonderer Prüfmerkmale mit Prüf- und FKT-Test-Anweisung, werden in unsere Arbeitsfolgen und Prüfkriterien integriert.

Imagefilm

"Wir wissen, wie moderne EMS-Dienstleistung geht"

Gewinnen Sie einen ersten Einblick in unser Unternehmen.

Imagefilm

"Wir wissen, wie moderne EMS-Dienstleistung geht"

Gewinnen Sie einen ersten Einblick in unser Unternehmen.